PRODUCTS

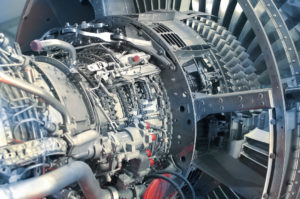

THERMOCOAX provides gas turbine production market with thermocouples done with specific sheath alloy as Haynes© for longer life, 24 000 operating hours. Our customers are using a lot of our high quality signal transmission cables for connecting with their strain gauges or other sensing elements when the environment is extreme with high temperature and noisy.

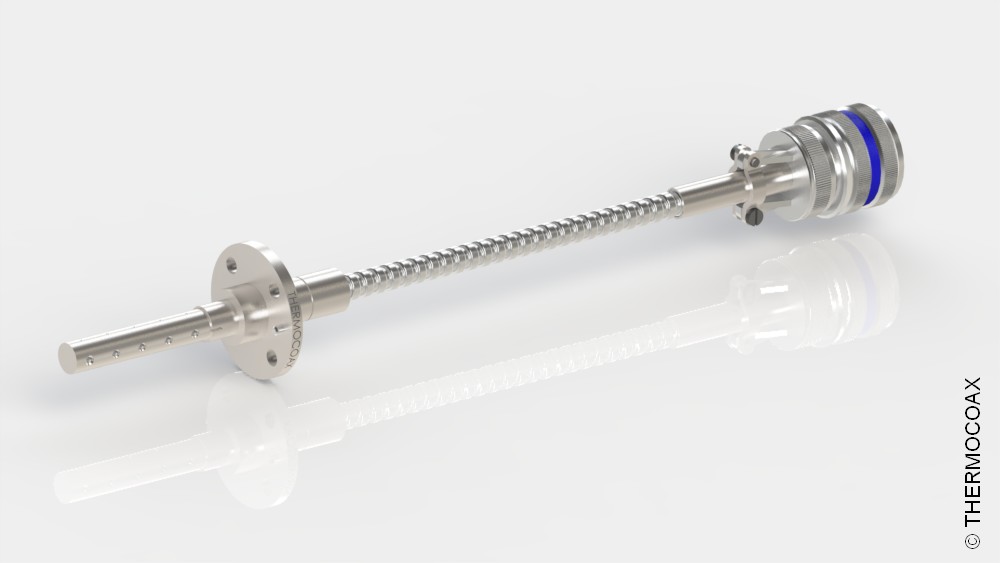

Based on our 1 500°C ceramic/metal brazing, THERMOCOAX provides to the market sensor solutions for Blade Tip Clearance, Blade Tip Timing and Debris monitoring sensors. The non-cooling design offers very integrated solution. The high quality triaxial cable offers a high signal quality, an excellent mechanical behavior when bended. Finally, THERMOCOAX is a key player for the maintenance.

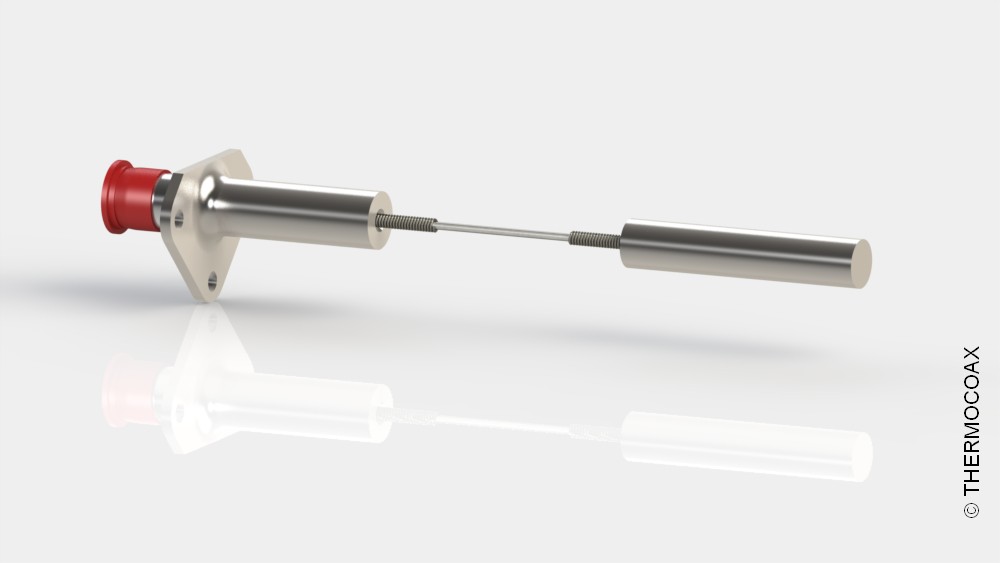

With the 1 000°C heaters, customer runs stress relieve after welding operation. With diameter as 0.5mm, customers shape the heaters to fit the request heat-treat area, by this way he avoids heavy and costly treatment in furnace.